Digital Shield Engineering: Precision Earthing & Lightning Protection Design Through CADD

Electrical systems power modern civilization. From high-rise commercial towers to manufacturing plants, hospitals, airports, and data centers, reliable power infrastructure supports every operation. However, while designers focus on efficiency and automation, one critical element often determines long-term safety and resilience: grounding and lightning protection. Without a well Earthing Lightning Protection Design system, even the most advanced installation becomes vulnerable to catastrophic damage.

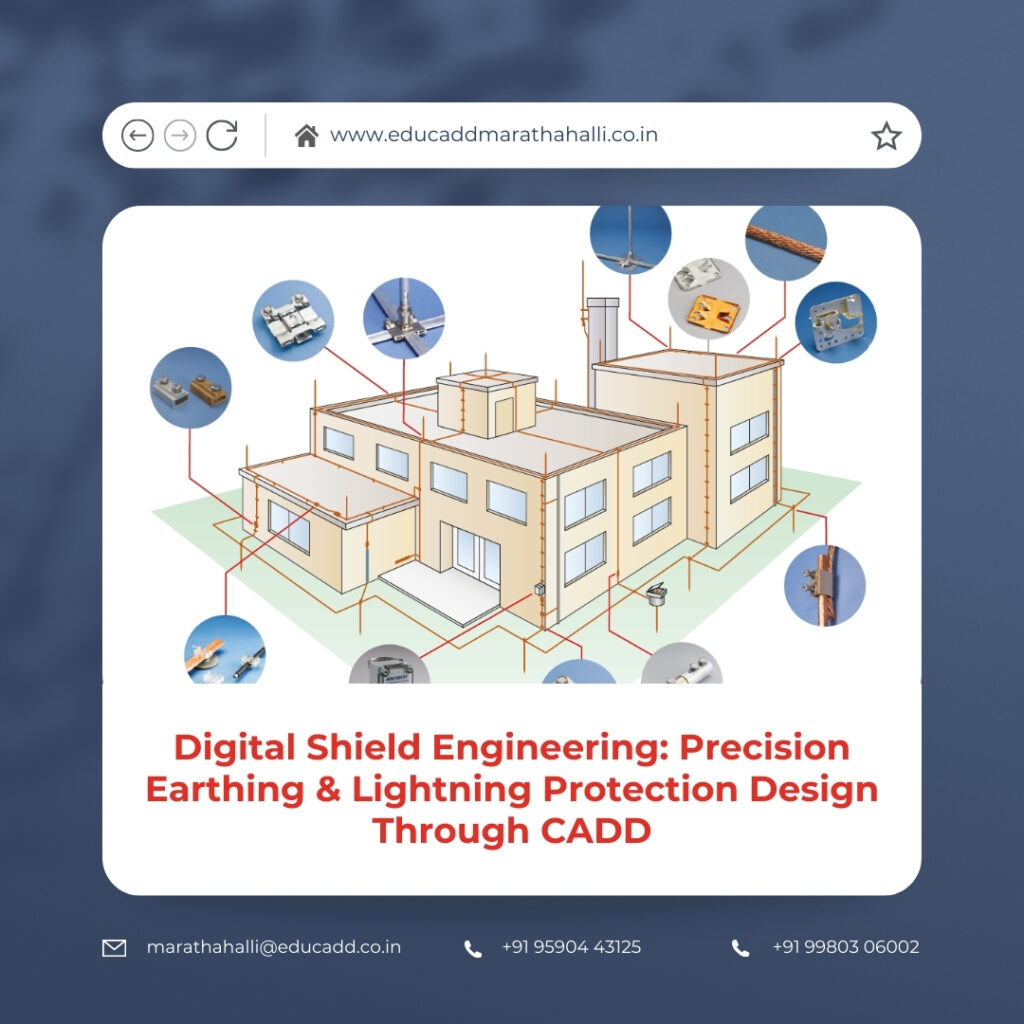

Earthing Lightning Protection Design

Today, engineering practices have evolved significantly. Manual drafting and rule-of-thumb calculations are no longer sufficient for complex projects. Instead, professionals rely on advanced digital tools to design, analyze, and optimize protective systems. Earthing & Lightning Protection Design Using CADD enables engineers to model electrical behavior, simulate fault scenarios, and produce highly accurate installation drawings. As a result, projects achieve higher reliability, better compliance, and enhanced safety performance. This comprehensive discussion explores the technical foundations, design methodologies, digital integration strategies, and future advancements in grounding and lightning protection design.

1. The Critical Role of Earthing in Electrical Infrastructure

Every electrical installation requires a stable reference point for voltage. Earthing provides this reference by connecting electrical systems directly to the ground through a low-resistance path. Consequently, it prevents dangerous voltage buildup and ensures safe dissipation of fault currents. When insulation fails or short circuits occur, the earthing system directs excess current safely into the soil instead of allowing it to energize exposed surfaces.

Moreover, grounding enhances system stability during transient conditions such as switching surges and lightning impulses. It protects transformers, switchgear, generators, and sensitive electronics from damage. Therefore, earthing is not simply a regulatory requirement; it forms the backbone of electrical safety.

Earthing Lightning Protection Design Using CADD strengthens this foundation by allowing engineers to analyze ground resistance values accurately. Digital platforms calculate electrode configurations, conductor cross-sections, and grid layouts with precision. Additionally, 3D visualization clarifies spatial relationships between grounding components and structural foundations. As a result, the design process becomes systematic, data-driven, and significantly more reliable.

2. Understanding Lightning Behavior and Structural Vulnerability

Lightning is a natural electrical discharge capable of delivering immense energy within microseconds. A single strike can produce currents exceeding 200 kA and temperatures hotter than the surface of the sun. When such energy interacts with buildings or industrial installations, structural damage, fire outbreaks, and equipment destruction may occur instantly.

Lightning protection systems aim to intercept strikes before they impact vulnerable structural elements. Air terminals capture the discharge, down conductors guide the current safely toward earth electrodes, and bonding networks equalize potential differences throughout the structure. Therefore, each component must function seamlessly within the overall system.

Through Earthing & Lightning Protection Design Using CADD, engineers can evaluate the zone of protection using rolling sphere analysis and protection angle methods. These simulations determine whether every part of the building remains within a safe protective envelope. Consequently, designers optimize air terminal placement and down conductor routing without excessive material usage.

3. Soil Characteristics and Ground Resistance Modeling

The performance of any grounding system depends heavily on soil resistivity. High-resistivity soil restricts current flow, which increases ground resistance and compromises protection. Therefore, soil investigation becomes the first technical step in grounding design.

Engineers conduct field tests using standardized methods such as the Wenner four-pin technique. The data collected provides insight into soil layers, moisture content, and seasonal variations. However, interpreting this information manually often leads to approximation errors.

Earthing Lightning Protection Design Using CADD enables engineers to input soil parameters into simulation software. The program then calculates optimal electrode depth, spacing, and configuration. Additionally, engineers can compare multiple scenarios to determine the most efficient arrangement. As a result, the final system achieves lower resistance values and greater operational stability.

4. Types of Grounding Configurations and Their Applications

Different facilities require distinct grounding approaches. Residential buildings often rely on pipe or plate earthing, while substations and heavy industrial sites demand extensive grid systems. Data centers and telecommunication hubs require highly controlled grounding networks to protect sensitive electronics.

Grid earthing distributes fault current over a broad area. This distribution reduces step and touch potentials, thereby minimizing risk to personnel. Conversely, vertical rods or strip earthing may suffice for smaller installations with lower fault levels.

Using Earthing & Lightning Protection Design Using CADD, engineers can develop detailed layouts of rods, strips, meshes, and bonding conductors. The software automatically calculates conductor lengths and intersection points. Furthermore, it provides clear construction drawings for installation teams. Consequently, design accuracy improves while project execution becomes more streamlined.

5. Managing Step and Touch Potential Risks

When fault current enters the ground, it creates voltage gradients around the electrode system. If a person walks across this gradient or touches grounded equipment, harmful current may pass through the body. Therefore, controlling step and touch potentials is essential, especially in substations and industrial plants.

Designers often increase grid density and add surface layers such as gravel to enhance surface resistivity. These measures reduce voltage exposure during fault events. However, determining safe limits requires careful calculation.

Earthing & Lightning Protection Design Using CADD assists engineers in modeling potential distribution across the entire site. Simulation tools identify high-risk areas instantly. Designers can then modify conductor spacing or add supplementary electrodes to maintain safe voltage limits. This digital approach ensures that personnel safety remains a top priority.

6. Regulatory Standards and Documentation Accuracy

International and national standards define grounding and lightning protection requirements. Organizations such as IEC and IEEE publish guidelines covering conductor sizing, protection levels, and acceptable resistance thresholds. Compliance with these standards ensures operational safety and legal accountability.

Manual documentation often consumes valuable time and may introduce inconsistencies. Missing calculations or unclear drawings can delay approvals and inspections.

Earthing & Lightning Protection Design Using CADD simplifies compliance management. The software generates standardized drawings, detailed calculation reports, and material schedules automatically. Consequently, project documentation becomes comprehensive and organized. Regulatory approval processes proceed smoothly because engineers can demonstrate compliance with confidence.

7. Lightning Risk Assessment and Structural Analysis

Not all structures face equal lightning risk. Factors such as building height, geographical location, occupancy type, and surrounding terrain influence strike probability. Therefore, designers must conduct thorough risk assessments before finalizing protection levels.

CADD-integrated tools evaluate these variables and determine the required class of lightning protection system. Engineers can simulate strike paths and verify protective coverage. As a result, air terminal placement aligns precisely with risk exposure.

Earthing & Lightning Protection Design Using CADD enhances decision-making by combining structural modeling with lightning analysis. Instead of relying solely on theoretical assumptions, engineers base their strategies on visualized data and calculated outcomes.

8. Integration with Modern Construction Workflows

Large-scale construction projects demand coordination between multiple disciplines. Electrical grounding networks must align with structural reinforcements, plumbing routes, and underground utilities. Without coordination, conflicts may arise during installation.

CADD platforms integrate seamlessly with BIM environments. Engineers can detect clashes early and modify layouts before construction begins. Additionally, 3D modeling improves communication among stakeholders.

Earthing & Lightning Protection Design Using CADD strengthens interdisciplinary collaboration. It ensures that grounding conductors, electrodes, and bonding networks fit precisely within structural designs. Consequently, project delays and costly rework decrease significantly.

9. Surge Protection Coordination and Bonding Strategies

Lightning strikes and switching operations generate transient overvoltages. These surges travel through power and communication lines, threatening electronic systems. Surge protection devices divert excess energy safely to ground, but their performance depends on effective bonding.

Proper bonding ensures that metallic components remain at equal potential during transient events. This coordination prevents differential voltages that could damage equipment.

Through Earthing & Lightning Protection Design Using CADD, engineers design comprehensive bonding networks. Simulation tools evaluate surge paths and grounding effectiveness. Consequently, protection extends beyond structural safety to include sensitive electronics and communication systems.

10. Material Selection and Lifecycle Considerations

Grounding materials must balance conductivity, durability, and cost. Copper offers excellent performance but increases capital expenditure. Galvanized steel provides affordability but may require corrosion protection in aggressive soil conditions.

Digital design tools calculate material quantities precisely. Engineers compare alternatives and analyze lifecycle costs. Therefore, they select materials that meet performance standards without exceeding budget constraints.

Earthing & Lightning Protection Design Using CADD enhances procurement planning by generating accurate bills of quantities. Additionally, digital records support maintenance scheduling and long-term asset management.

11. Construction Drawings and Field Implementation

Clear and accurate drawings guide installation teams effectively. Depth specifications, routing paths, and bonding connections must remain unambiguous.

CADD-generated layouts provide detailed annotations and dimensioning. Engineers can update drawings quickly if site conditions change. Moreover, digital files allow easy sharing across teams.

Earthing & Lightning Protection Design Using CADD ensures consistency between design intent and on-site execution. This alignment improves installation quality and minimizes errors during construction.

12. Testing, Commissioning, and Maintenance Strategy

After installation, engineers measure ground resistance and verify system performance. Over time, environmental factors such as corrosion and soil drying may affect grounding efficiency. Therefore, routine inspection remains essential.

Digital documentation simplifies maintenance planning. Technicians can locate electrodes and bonding points using updated design files. Additionally, historical test data remains accessible for comparison.

Earthing & Lightning Protection Design Using CADD supports long-term reliability by enabling systematic record keeping and periodic evaluation. Consequently, system performance remains consistent over decades.

13. Cost Efficiency Through Digital Optimization

Budget control remains a key concern in infrastructure projects. Overdesign increases expenses, while underdesign compromises safety. Therefore, achieving balance requires accurate modeling and analysis.

CADD software performs complex calculations rapidly. Engineers test multiple design scenarios and select the most efficient option. This process reduces material waste and prevents unnecessary expenditure.

Earthing & Lightning Protection Design Using CADD promotes cost efficiency without sacrificing protection standards. Furthermore, digital workflows shorten design timelines, which accelerates project delivery.

14. Future Developments in Intelligent Grounding Systems

Technology continues to advance rapidly. Smart monitoring systems can now measure ground resistance in real time. Cloud-based platforms enable remote collaboration among engineering teams worldwide.

In the future, artificial intelligence may optimize grounding layouts automatically based on environmental data. Predictive analytics could identify potential failures before they occur. Consequently, maintenance strategies will become proactive rather than reactive.

Earthing & Lightning Protection Design Using CADD will remain central to these advancements. As digital engineering evolves, grounding systems will become more intelligent, efficient, and resilient.

Conclusion

Electrical infrastructure must withstand faults, surges, and natural phenomena without compromising safety. Effective grounding and lightning protection systems provide this resilience. However, achieving optimal performance requires precision, analysis, and regulatory compliance.

Earthing Lightning Protection Design Using CADD transforms traditional drafting into an advanced digital engineering discipline. It enhances accuracy, improves collaboration, and ensures comprehensive documentation. Moreover, it strengthens safety through simulation and predictive analysis. As infrastructure grows more complex and technology advances, digital design methodologies will continue to shape the future of electrical protection systems, ensuring secure and sustainable development for generations to come.